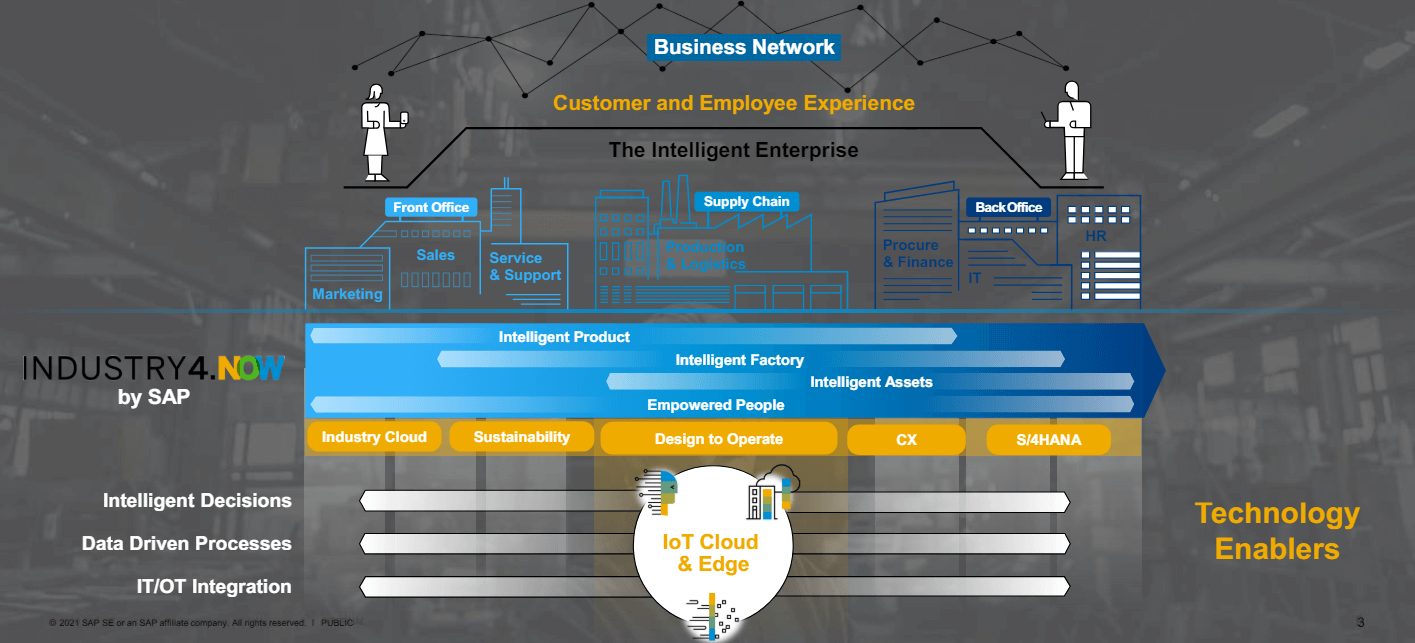

During the revolution of Industry 4.0, manufacturers are facing novel challenges like never before; from disturbances in supply chains to ever-growing customizations and sustainability concerns by customers. To get through such intricate situations, implementing digital transformation is no longer something you choose to do, but rather a must. It is in this regard that SAP Digital Manufacturing plays a critical role since it comes as an all-encompassing answer for creating an intelligent enterprise platform that delivers a wide range of intelligent enterprise technologies and applications specifically designed to empower manufacturers.

So, what is Industry 4.0?

Industry 4.0 marks a transformative era in manufacturing, integrating intelligent digital technologies into the industrial processes’ core. Industrial IoT, artificial intelligence, big data analytics, robotics, and automation are examples of cutting-edge technologies used in this phase of industrialization. This marked a turning point in the world when technologies like cloud computing and e-commerce were developed. By doing this, businesses now rely more on databases which were not available in the past.

Industry 4.0 has revolutionized business operations, altering the processes of producing and distributing goods. Advanced technologies such as the Industrial Internet of Things (IIoT), cloud connectivity, artificial intelligence and machine learning have been incorporated into manufacturing to make it more cohesive. This transformation allows products, factories and assets to be linked together in an intelligent manner.

Manufacturing Challenges in 2024

Manufacturing today faces countless challenges that can impact growth and operational efficiency. At the core, siloed and disconnected systems, along with manual processes, create significant barriers across the manufacturing landscape. In addition to compromising data transparency, these issues also prevent consistent performance measurement across different plants and contract manufacturers.

In addition, there is difficulty concerning optimization of the current capacity of labor and equipment. Manufacturers have problems changing production resources so they can meet changing demands. This problem is more severe while taking up modular and hybrid techniques in manufacture that are key to present-day production environments.

Still, many factory lines depend hugely on human interventions leading to silos of automation which prevent seamless performance. Apart from causing production delays, the high level of involvement slows down production as well as impacting overall uptime and performance of assets. However, the haphazard performance of assets can result in serious operational inefficiencies.

Additionally, when there are no actuators and sensors in the manufacturing process, this usually means that there is no real-time data, which makes it difficult to quickly respond to problems, optimize and improve on how things are produced. This situation highlights how badly we need digitized strategies for combining both automations and controls used in manufacturing since they help streamline operational processes leading to an enhanced capacity to produce goods at lower costs but higher quality levels than before.

How can SAP Digital Manufacturing improve this?

SAP Digital Manufacturing can boost sustainable and risk-resilient manufacturing. It optimizes production by integrating execution, visibility, and analysis through:

- Cloud deployment

- Top floor and shop floor visibility

- KPIs tracking and analytics

- Precise execution of production processes

- Improved operation productivity with ML for visual inspection

SAP Digital Manufacturing Key Features

Offer meaningful data, for example you can:

- Define and leverage various production models

- Map out operational events and control systems

- Use analytics and self-service reports on KPIs and live operations data

Harmonized, reliable analytics

- Access data from numerous manufacturing systems

- Integrate data from manufacturing with SAP S/4HANA and SAP ERP

- Integrate with MES systems, such as SAP Manufacturing Execution and SAP Manufacturing Integration and Intelligence

Unified manufacturing modeling

- Built based on industry standards

- Defining KPIs using modeling environment and harmonized data model

- Appling existing and predetermined integration standards

The above is just a slight introduction to SAP Digital Manufacturing for more in-depth insights, book a consultation with our team.

As a final point, industry 4.0 tools and solutions like SAP Digital Manufacturing allow you to collect, analyze, and interpret vast amounts of data in real time – so you can quickly get actionable insights, enabling you to make accurate and confident decisions. Same goes for customers too, as their demands and expectations are constantly changing. Therefore, real-time data analytics will help you adapt quickly, personalize your offering, and provide tailored solutions on demand.

There is a lot of competition and volatility in our lives today. Tools and strategies within Industry 4.0 can be used to improve efficiency and productivity while also gaining a meaningful competitive advantage.